99.9% White fused aluminum oxide powder for plasma spraying

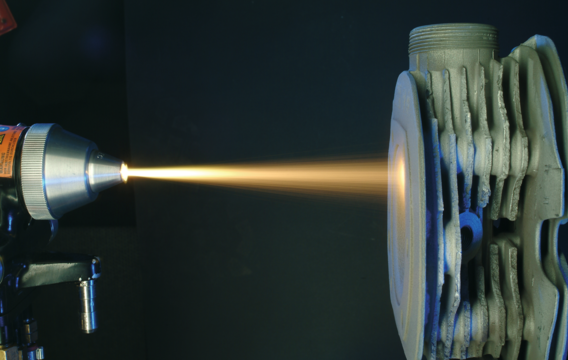

Aluminum oxide plasma spraying is a special surface treatment technology. It’s widely used in fields such as automotive manufacturing, aerospace components, electronic equipment, medical equipment, etc. It prevents the metal from being directly exposed to the air by spraying a coating on the metal surface. This can improve the basic requirements for rust prevention and aging of metals. Using aluminum oxide coating as a spraying material can also improve the high-temperature resistance, corrosion resistance, wear resistance, and oxidation resistance of the workpiece. Here are the characteristics of 99.9% white fused aluminum oxide powder 600 # for plasma spraying.

1. High Al2O3 purity

The purity of ordinary industrial alumina is around 98%. The aluminum oxide treated by high-temperature electric melting will be further purified. The main components after purification are α- Al2O3. The purity of 3N white fused aluminum oxide 600 # is not less than 99.9%. The special smelting process makes a high alpha conversion rate.

2. the hardness and refractory temperature

The sodium and silicon content of high-purity fused alumina micro powder are less than 200ppm. Moreover, the hardness and refractory temperature are better than those of normal WFA powder.

3. Low iron content

Iron residues are harmful to the oxidation and corrosion resistance of materials. Therefore, the iron content in high-purity white corundum is less than 200ppm, which can effectively control iron residue.

4. Uniform particle size distribution

Uniform particle size distribution helps the spray powder coat evenly on the surface. It prevents the risk of local lack of coating protection. High purity white corundum micro powder with a particle size of 600 #, with a D50 of 27-28 microns and 80% of particles concentrated in 15-60 microns, resulting in high particle size concentration.

5. Pure white color

The appearance of high-purity alumina micro powder is pure white. It is beneficial for the good appearance of the coating after spraying.